FEATURED PROJECTS

THE NORTHERN RD STAGE 2 UPGRADE PROJECT

Penrith, NSW

Project Overview: JK Williams specialises in unique roadway solutions with a rich history of innovation in its 60+ years. JK Williams was engaged by Lendlease Engineering for The Northern Road Stage 2 upgrade works, tasked with delivering a more efficient and sustainable solution. Weldlok and JK Williams have fostered a successful working relationship across many years and was consulted early in the design phase to provide a grating solution compatible with new precast technology.

Challenge:

Cast-iron grated trench grates have been widely used in Australia across many roadway projects. For this large-scale construction, standard trench grates presented challenges for labour speed and energy use as daily outputs are typically limited to 30 meters. For a project stretching 14kms, the current standard was going to be laborious and expensive for the asset owner.

Weldlok was to design a custom solution that supported an innovative new method.

JK Williams Projects Director, Marc Bore, sought to develop a new methodology of construction where slip forming can take place on-site and sought to consult with Weldlok to design and develop a custom galvanised trench grate that works with the new technology to achieve a single pour with the trench grate in place, increasing both daily productivity and the quality of the works.

Solutions:

Weldlok was consulted early in the project to support JK Williams through the design analysis and feedback process with the LendLease project team. The mandate was to create a compliant system that was quick and superefficient creating a reduction in cost, time and labour. A series of custom-made galvanised steel grating drains were manufactured for trials and development, with adjustments to engineering and design requirements as a result of rigorous testing of the new method at the JK Williams facility in Penrith, NSW. Concurrently, the Weldlok Civil products team conducted extensive load testing through the NATA accredited facility in Yagoona, NSW, to ensure each iteration of the new galvanised steel trench grate design was compliant and exact in its specifications.

The critical element was the client tolerances were close to -0/+0 which required exact precision in the quality and uniformity of products.

Shifting from traditional cast iron to galvanised steel was critical to achieving the desired quality and productivity outcomes. Weldlok depth of knowledge and inhouse capabilities, including local manufacturing, sourcing and engineering which allowed the business to fully support the vision of the JK Williams team

Results:

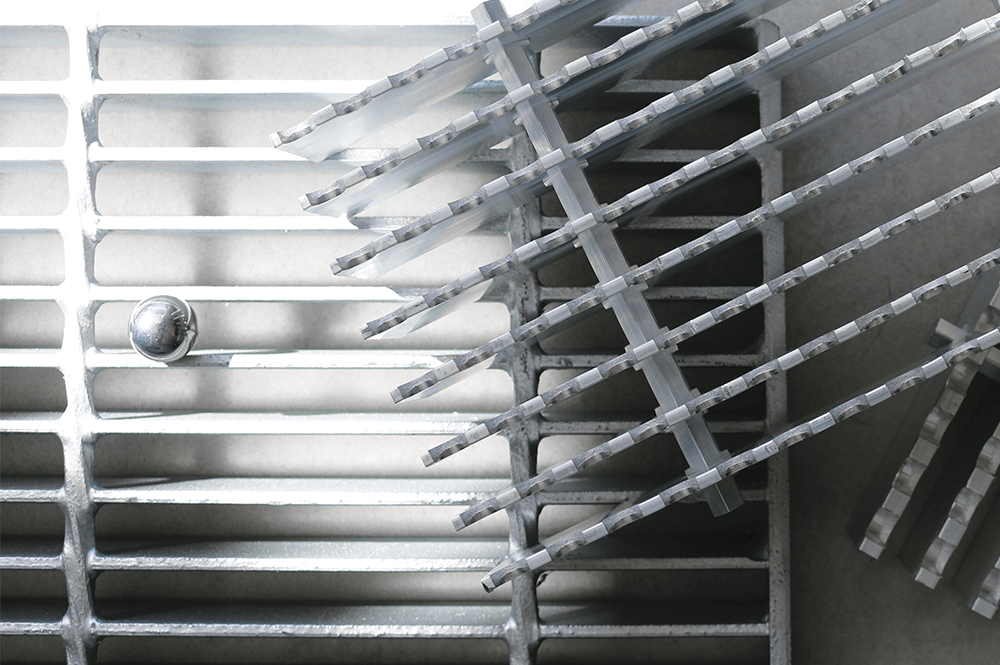

The result was the development of a new galvanised steel grate, specifically designed to work seamlessly with the newly-developed slip form method. The TGF0240D2-C features a specifically engineered design profile and steel frame, pairing with JK Williams modified mould. The product was approved for use by Transport for NSW, allowing JK Willams to deliver a more efficient slip-formed trench grates solution.

The finished slip formed trech grate drain (credit: JK Williams) Named after the traditional owners, the Dharug people, the ‘Badu Muru’ drain means ‘water path’, aptly coined by LendLease Engineering. The Badu Muru system, slip formed on-site by JK Williams with galvanised steel grates from Weldlok delivered well over 100 metres daily, significantly exceeding the conventional 30 meters per day of grated trench drain. The custom-designed product works with JK Williams technology to significantly accelerate project completion with no loss to quality, load-bearing capacity or compliance. The design is patent-pending providing a unique point of difference in the market.

Client Feedback

Marc Bore, Projects Director at JK Williams Group, reflected “From the outset, our overarching objective was to identify a way to improve the method of grated trench drain. On reflection, with Weldlok we achieved a fit for purpose design alternative which altered segregated trench drain applications to a monolithic structure installation over large quantities.”

View